The rapid development of electric vehicles (EVs) has intensified the demand for advanced materials that enhance safety, efficiency, and durability. Among such innovations, Ceramic Silicone Foam has emerged as a vital material in improving electric vehicle performance, particularly within the new energy sector.

Understanding Ceramic Silicone Foam: Composition and Characteristics

This combination results in a material with:

Outstanding thermal insulation (withstanding temperatures over 1000°C)

Excellent flame retardancy and thermal runaway protection

Superior mechanical flexibility and resilience

Chemical and environmental resistance

Role of Ceramic Silicone Foam in Thermal Runaway Protection for EV Batteries

One of the most critical concerns in electric vehicle design is battery safety, particularly managing thermal runaway — a hazardous condition where lithium-ion batteries overheat uncontrollably, potentially leading to fires or explosions. Ceramic Silicone Foam plays a pivotal role in addressing this risk.

When a battery cell begins to overheat, the foam’s high-temperature resistance creates an effective thermal barrier, preventing heat transfer to neighboring cells. Its flame-retardant properties further suppress ignition, buying crucial time for safety mechanisms to activate.

The foam’s compressibility also allows it to maintain intimate contact with battery components, enhancing heat dissipation and reducing hotspots. Moreover, its chemical inertness prevents degradation or reaction with battery electrolytes, thus ensuring long-term reliability.

This thermal runaway protection is vital in maintaining vehicle safety, preserving battery lifespan, and supporting regulatory compliance for EV manufacturers.

Enhancing EV Performance Through Vibration and Noise Reduction

Electric vehicles, while quieter than combustion engines, still face challenges related to vibrations and noise generated by electric motors, battery packs, and road interaction. Ceramic Silicone Foam’s inherent elasticity and damping qualities contribute significantly to reducing these mechanical disturbances.

By strategically integrating this foam in battery modules, motor housings, and chassis interfaces, EV designers can absorb shocks and vibrations that would otherwise degrade electronic components or create noise discomfort for passengers.

Reduced vibration not only improves passenger comfort but also prevents premature wear of sensitive electronic parts, ultimately enhancing vehicle reliability and extending maintenance intervals.

This multifaceted contribution highlights ceramic silicone foam’s role beyond thermal management, extending into mechanical performance optimization.

Lightweight Design and Energy Efficiency: The Foam’s Contribution

Weight reduction remains a fundamental objective in electric vehicle engineering. Lighter vehicles require less energy for acceleration and maintain better overall efficiency, directly impacting driving range and energy consumption.

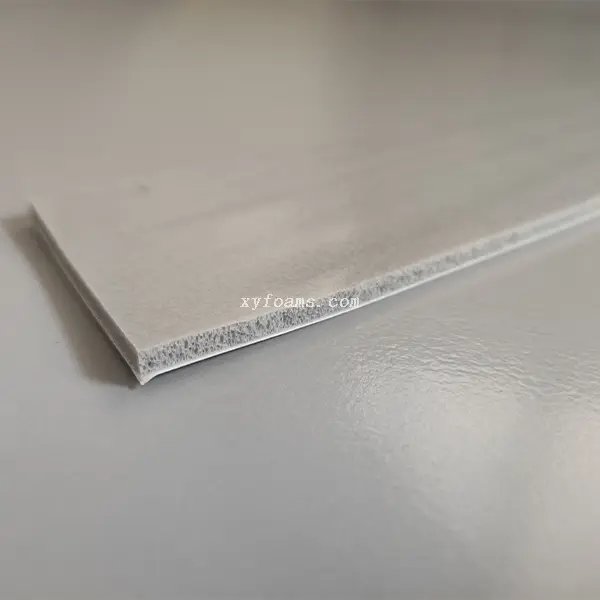

Ceramic Silicone Foam is exceptionally lightweight due to its porous foam structure. Despite its lightness, it does not compromise structural integrity or protective qualities. Its application in battery modules, thermal insulation panels, and sealing components helps reduce the total vehicle mass.

Compared with traditional heavy insulation materials, ceramic silicone foam enables designers to optimize weight distribution without sacrificing safety or durability. This reduction in weight contributes to:

As a result, the foam aligns perfectly with the goals of new energy vehicles seeking to maximize driving distance while maintaining robust safety standards.

Durability and Environmental Resistance for Long-Term EV Reliability

Electric vehicles are exposed to a wide range of environmental conditions, including moisture, dust, temperature extremes, and mechanical stress. Ceramic Silicone Foam’s resilience to these factors plays a critical role in guaranteeing the longevity and consistent performance of EV systems.

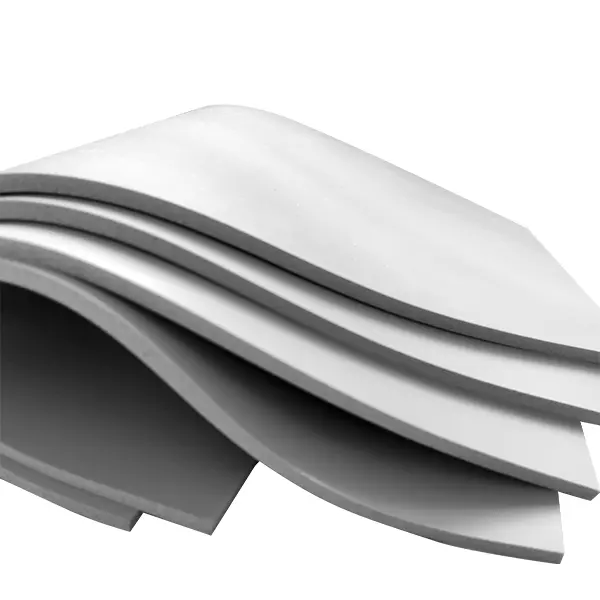

The material’s resistance to UV radiation, ozone, and chemical exposure means that it does not degrade prematurely, maintaining its protective functions over the vehicle’s lifecycle. Its flexibility prevents cracking or crumbling even under repeated thermal cycling or mechanical compression.

Furthermore, the foam’s hydrophobic properties limit water ingress, protecting battery cells and electronic modules from corrosion or short-circuit risks. This environmental robustness ensures fewer failures and maintenance costs for EV owners.

This durability factor is especially important in new energy sectors where vehicles must perform reliably across diverse climates and conditions.

Table: Key Properties of Ceramic Silicone Foam Relevant to EV Applications

| Property | Description | Benefit to EV Performance |

| Thermal Stability | Withstands temperatures >1000°C | Protects against thermal runaway and heat damage |

| Flame Retardancy | Self-extinguishing and flame-resistant | Enhances battery fire safety |

| Mechanical Flexibility | Compressible, vibration-damping | Reduces noise and vibration, prolongs component life |

| Lightweight | Low density due to porous foam structure | Improves vehicle efficiency and range |

| Chemical Resistance | Resistant to oils, solvents, ozone, UV radiation | Ensures long-term durability and safety |

| Moisture Resistance | Hydrophobic and impermeable to water | Prevents corrosion and electrical faults |

Frequently Asked Questions (FAQ)

1. What makes ceramic silicone foam superior to traditional insulation materials in EVs?

Ceramic silicone foam uniquely combines high-temperature resistance with elasticity and low weight. Traditional materials may offer insulation but often lack flexibility or are heavier, affecting vehicle efficiency and design adaptability. Ceramic silicone foam’s multi-functional properties provide superior thermal management while reducing vibration and weight.

2. How does ceramic silicone foam help in preventing EV battery fires?

By acting as a thermal barrier and flame retardant, ceramic silicone foam prevents heat from spreading during a thermal runaway event in a battery pack. This containment reduces the chance of fire propagation and gives onboard safety systems more time to respond, significantly enhancing overall battery safety.

3. Can ceramic silicone foam be customized for different electric vehicle designs?

Yes. Ceramic silicone foam can be tailored in density, thickness, and shape to fit various battery module designs, motor housings, or structural components. This flexibility allows EV manufacturers to integrate the foam precisely where thermal protection or vibration damping is most critical.

4. Is ceramic silicone foam environmentally friendly?

Ceramic silicone foam is chemically stable and does not release harmful substances under normal operation. Moreover, its durability reduces the need for frequent replacement, contributing to sustainable vehicle life cycles. However, disposal methods must comply with local environmental regulations.

Conclusion

In the fast-evolving landscape of new energy vehicles, materials that offer superior safety, efficiency, and reliability are paramount. Ceramic Silicone Foam addresses these needs by providing exceptional thermal insulation, flame retardancy, mechanical flexibility, and environmental resistance.

Its multifaceted benefits—from thermal runaway protection to vibration damping and lightweight design—directly contribute to improving electric vehicle performance and safety. As EV technology advances, the role of innovative materials like ceramic silicone foam will become increasingly critical in meeting stringent industry standards and consumer expectations.

Investing in and integrating ceramic silicone foam technology enables manufacturers to enhance battery safety, maximize driving range, and deliver a smoother, more reliable ride. Its proven properties make it an indispensable component in the ongoing transformation towards sustainable, high-performance electric mobility.