Introduction

In the accelerating shift towards renewable energy, ensuring safety, efficiency, and durability in outdoor energy installations is paramount. As solar panels, wind turbines, and battery storage systems increasingly dominate the energy landscape, materials that can withstand harsh environmental conditions while delivering optimal performance are in high demand. Among these, Ceramifiable Silicone Foam has emerged as a compelling solution for thermal management and safety protection.

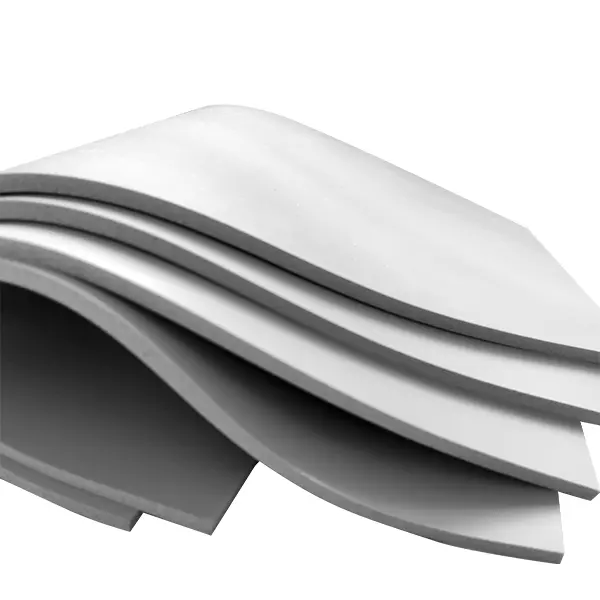

Ceramifiable Silicone Foam is a unique multifunctional material that combines the flexibility and resilience of silicone with the ability to form a dense, ceramic-like insulating layer under high temperatures. This effect is not achieved by mixing ceramic particles into the silicone; instead, special flame retardants are incorporated. When exposed to fire or extreme heat, these additives enable the material to transform into a compact ceramified barrier, providing effective thermal insulation and protection. This article explores the suitability of ceramifiable silicone foam for outdoor renewable energy applications, highlighting its properties, practical benefits, and common questions related to its deployment.

What is Ceramic Silicone Foam and Why Does It Matter for Renewable Energy?

At its core, ceramifiable silicone foam is a porous, lightweight material engineered to maintain the elasticity and cushioning performance of silicone while offering additional safety benefits. Unlike conventional silicone foams, it does not rely on ceramic fillers. Instead, through the addition of flame retardants, it achieves a transformation under high temperatures, forming a protective ceramified layer that significantly improves thermal shielding.

For renewable energy systems—especially outdoor installations like solar farms, wind energy converters, and energy storage units—thermal management is crucial. Overheating in these systems can lead to thermal runaway, a dangerous chain reaction causing equipment failure or fire hazards. Ceramifiable silicone foam helps mitigate such risks by providing both flame retardancy and the ability to withstand elevated temperatures without rapid degradation.

Additionally, the foam’s porous structure provides excellent insulation while maintaining flexibility, making it suitable for vibration damping, sealing, and shock absorption. It also demonstrates good resistance to UV radiation, moisture, and a wide range of chemical agents. While not absolutely inert, its stable behavior against environmental factors reinforces its suitability for outdoor use, where exposure to sunlight, rain, and pollutants is unavoidable.

Key Advantages of Ceramic Silicone Foam in Outdoor Renewable Energy Installations

1. Superior Thermal Runaway Protection

Battery energy storage systems (BESS) are integral to renewable energy grids, but they carry risks related to thermal runaway events. Ceramic silicone foam can be used as a protective barrier to slow or prevent the propagation of fire or excessive heat from one cell to another. This containment capability is critical to safeguarding entire battery packs and preventing catastrophic failures.

2. Weather Resistance and Durability

Outdoor renewable energy installations face relentless environmental stresses—UV radiation, temperature fluctuations, moisture, and pollutants. The inherent chemical inertness and UV stability of ceramic silicone foam ensure that it does not degrade or lose functionality over time, even after prolonged exposure.

3. Mechanical Flexibility and Lightweight Nature

The foam’s flexibility enables it to conform to irregular surfaces, creating effective seals around sensitive components such as battery modules or electrical connectors. At the same time, its lightweight nature prevents adding excessive weight to structures like solar panel frames or turbine housings.

4. Environmental Safety and Sustainability

Unlike some conventional insulation materials, ceramic silicone foam is free from halogenated compounds, making it safer for both users and the environment. Its long lifespan reduces the need for frequent replacement, aligning with the sustainability goals of new energy sectors.

Applications of Ceramic Silicone Foam in New Energy: Detailed Use Cases

Solar Panel Systems

Solar farms require materials that protect electrical components from overheating and moisture ingress. Ceramic silicone foam can be integrated into junction boxes, inverter housings, and cable seals. By maintaining consistent thermal insulation and sealing performance, it ensures efficiency and longevity of solar arrays.

Wind Turbine Components

In wind energy, protecting control electronics and battery backup systems is vital. Ceramic silicone foam serves as an insulator and shock absorber inside nacelles and tower-mounted battery units, safeguarding against mechanical vibration and temperature spikes.

Energy Storage Systems (ESS)

Energy storage is a cornerstone of renewable grids. Here, ceramic silicone foam is often employed in battery modules to provide flame retardancy and thermal insulation. It helps control thermal runaway propagation, preventing escalation of localized failures into large-scale incidents.

Electric Vehicle (EV) Charging Stations

The increasing deployment of EV charging infrastructure also benefits from ceramic silicone foam. It offers effective sealing against dust and water ingress, while managing heat dissipation in high-power electronic components, thus enhancing operational safety and durability.

Technical Properties of Ceramic Silicone Foam Relevant to Outdoor New Energy Installations

| Property | Description | Benefit for Renewable Energy Applications |

| Thermal Stability | Resistant to temperatures up to 1000°C | Protects battery cells and electronics from heat damage |

| Flame Retardancy | Meets UL 94 V-0 fire safety standards | Prevents fire propagation, enhances safety |

| Moisture Resistance | Impermeable to water and high humidity | Prevents corrosion and short circuits |

| Chemical Inertness | Resistant to acids, alkalis, and other chemicals | Suitable for harsh environments |

| Mechanical Flexibility | Compressible and elastic | Easy installation and vibration dampening |

| Density | Lightweight foam structure | Does not add significant weight to installations |

This combination of properties makes ceramic silicone foam a highly versatile material for renewable energy equipment subjected to outdoor environments.

Can Ceramic Silicone Foam Withstand Outdoor Environmental Challenges?

Outdoor renewable energy installations expose materials to complex conditions—extreme temperatures ranging from subzero to over 60°C, intense UV radiation, rainfall, humidity, dust, and even chemical pollutants. Ceramic silicone foam is designed precisely to cope with these challenges.

The ceramic fillers embedded in the silicone matrix confer outstanding UV resistance, preventing the breakdown of polymer chains that typically cause cracking or brittleness. Additionally, the foam’s closed-cell or semi-open-cell structure prevents water absorption, thus eliminating risks of swelling or microbial growth.

Thermal cycling is another critical factor, as temperature swings can cause expansion and contraction stresses. The elasticity of silicone combined with ceramic reinforcements allows the foam to maintain its dimensional stability and sealing integrity over thousands of cycles.

In essence, ceramic silicone foam is engineered to retain its protective and insulating properties throughout the typical lifespan of outdoor renewable energy equipment, making it a reliable choice for field applications.

Frequently Asked Questions (FAQ) About Ceramic Silicone Foam in Renewable Energy

Q1: Is ceramic silicone foam suitable for both high and low temperature extremes?

Yes, ceramic silicone foam can maintain performance under wide temperature ranges, often from -60°C to +240°C or higher depending on formulation. This makes it ideal for outdoor installations in diverse climates.

Q2: How does ceramic silicone foam improve safety in battery storage systems?

By acting as a thermal barrier and flame retardant, the foam slows the spread of thermal runaway fires between battery cells, reducing the risk of large-scale fires and damage.

Q3: Can ceramic silicone foam be customized for different thicknesses or densities?

Absolutely. The foam’s manufacturing process allows tailoring of density and thickness to suit specific insulation, sealing, or mechanical protection requirements.

Q4: Does ceramic silicone foam degrade when exposed to UV or moisture outdoors?

No. The material is designed for high UV resistance and moisture impermeability, ensuring long-term durability in outdoor renewable energy installations.

Q5: Is ceramic silicone foam environmentally friendly?

Yes, it contains no halogens or harmful chemicals, and its durability reduces the need for frequent replacement, contributing to sustainability.

Conclusion

The renewable energy sector demands materials that combine safety, performance, and environmental resilience. Ceramic silicone foam meets these criteria through its unique composition and versatile properties. Its ability to provide thermal runaway protection, resist harsh environmental conditions, and maintain mechanical flexibility makes it an excellent material choice for outdoor new energy installations.

Whether in solar power arrays, wind turbines, energy storage batteries, or EV charging stations, ceramic silicone foam enhances operational safety and reliability. As new energy technologies continue to evolve, the role of advanced materials like ceramic silicone foam will only grow more critical in building a sustainable, resilient energy future.